Electric cooperatives not only lead the utility industry in implementing energy-efficiency programs and supplying power from renewable energy, they also are on the cutting edge when it comes to testing and deploying carbon capture and storage technology (CCS).

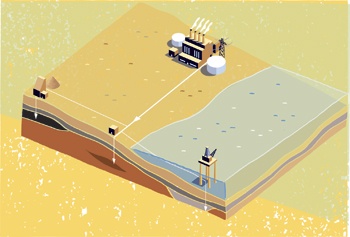

This technology involves isolating carbon dioxide—a gas blamed for contributing to climate change—from coal- and gas-fueled power-plant emissions. The collected gas is then compressed, pumped down into spent oil and natural gas wells, saline reservoirs or inaccessible coal seams and, in theory, entombed forever.

As we strive to meet increasing demands for safe, reliable and affordable electricity in an environmentally responsible fashion, CCS stands, according to a Massachusetts Institute of Technology report, “as the critical enabling technology to reduce carbon dioxide emissions significantly.”

A 2007 study released by the Electric Power Research Institute (EPRI), a nonprofit, utility-sponsored organization whose members include electric co-ops, finds that CCS technology is the most significant among seven principal areas where U.S. electric utilities can help cut carbon dioxide emissions.

If electric utilities are to implement CCS on a commercial scale by 2020—the cornerstone of EPRI’s framework for keeping the lights on and rates affordable as the nation tackles climate change—in-depth research and demonstration projects are needed.

The 2009 American Recovery and Reinvestment Act, known as the stimulus bill, provides $3.4 billion for CCS programs. These funds will support fossil-energy research and development, carbon capture and energy-efficiency improvement projects.

Basin Electric Power Cooperative secured a $300 million federal loan in early 2009 from the U.S. Department of Agriculture for a CCS demonstration project at its 900-megawatt (MW) coal-fired Antelope Valley Station. The Bismarck, North Dakota-based generation and transmission (G&T) co-op supplies wholesale power to 126 member co-ops in nine states.

Approximately 1 million tons of carbon dioxide will be captured annually from the 120-MW project, making this demonstration, expected to go online in 2012, one of the largest in the world. But a CCS venture of this scale faces significant technical and economic challenges: Transferring this technology to a large-scale, existing coal-fired power plant has never been done.

“We’ve been pushing the technology envelope for years, while keeping an eye on consumer electric costs. But these efforts take time and a huge financial commitment,” said Basin Electric Power Cooperative CEO and General Manager Ron Harper. “Our demonstration project has the potential to create a viable path for coal in our nation’s energy future. The conundrum for us lies in paying for the technology and research necessary to do this work, while keeping electricity affordable for our member-owners.”

The Great Plains Synfuels Plant, a natural gas plant owned and operated by Basin Electric Power, started delivering captured carbon dioxide in 2000 to a Canadian oil producer. The plant starts the process with coal, which is turned into a synthetic natural gas. Every day, the Synfuels plant sends 8,700 tons of captured, compressed carbon dioxide via a 205-mile-long underground pipeline to depleted oil fields in Weyburn, Saskatchewan, where the gas helps bring more oil to the surface.

Great River Energy—a Maple Grove, Minnesota-based G&T co-op—is one of five electric utilities taking part in a 2009 EPRI study to evaluate the impact of retrofitting existing coal-fired power plants with CCS technology. “We want to learn how we can capture carbon dioxide from our existing coal plants and thus continue to have a fleet of power plants that is productive, cost-effective and fulfills our duty to be good environmental stewards,” says Rick Lancaster, Great River Energy’s vice president of generation.

Here in Texas, the Legislature recently approved tax breaks for “clean-coal” plants to capture and store carbon dioxide.

——————–

Jennifer Taylor and Megan McKoy write about consumer and cooperative affairs for the National Rural Electric Cooperative Association.